The belt grinder is one of the most important tools for knife makers. It helps them remove material from metal blades to shape them into a perfect blade.

While it may seem easy to build your own belt grinder, there are a few things you need to know first. This will help you get the best results from your machine and make sure it runs well.

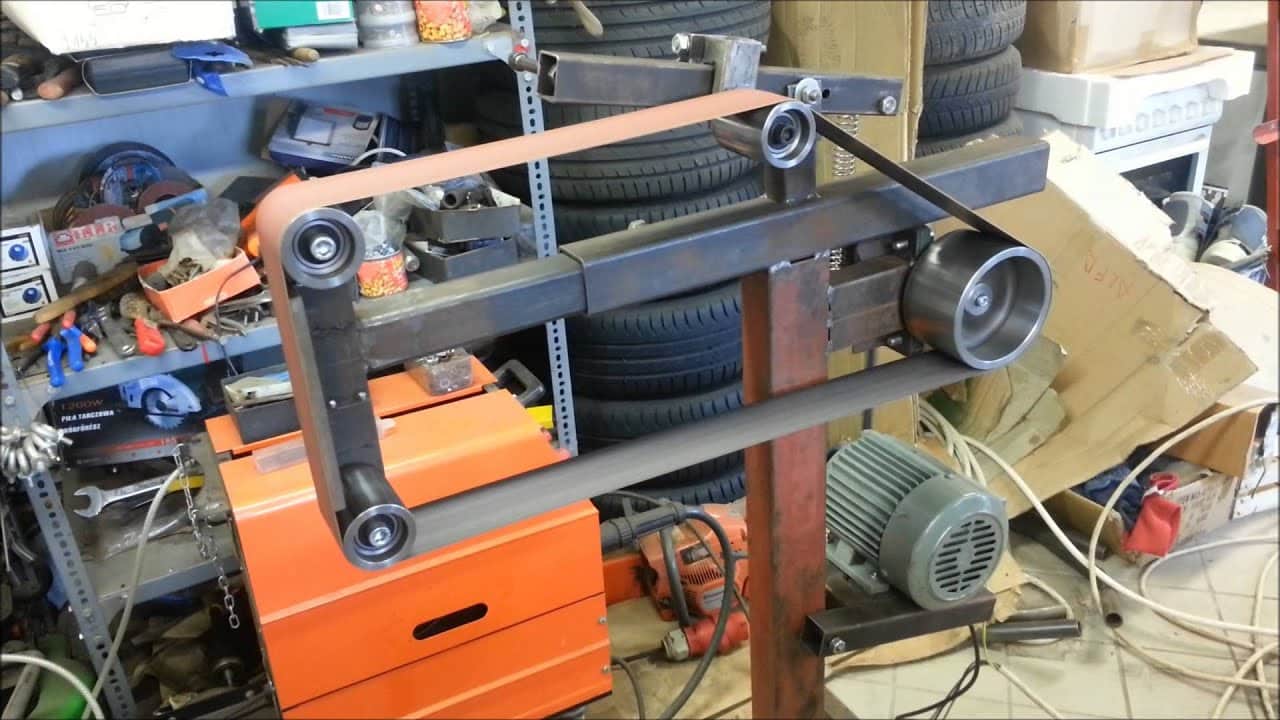

How to Make a Belt Grinder

When it comes to knife making, a belt grinder is an essential tool. It’s used to grind the steel of your blade, and it’s also a great way to shape the bevels.

The type of belt grinder that you get is a big factor in how effective your grinding process will be. The larger the machine, the more powerful it is likely to be.

Another thing to consider is the size of the belts it can support. While 2×72 inches are the industry standard, smaller sizes, such as 1×30 or 1×42, can be good options for hobbyists.

A belt grinder can be flat or round, and you’ll need to choose one that supports the purpose for which you want it. For example, if you’re grinding bevels on the knife, you’ll want a grinder with a flat platen to make the job easier and faster.

In general, a smaller machine is easier to change the belt on, but professional knifemakers will probably prefer a bigger grinder because it will be more powerful.

Tip 1: Buy a Belt Sander

Whether you’re a professional knife maker or just getting started, a belt grinder can make a big difference in the quality of your knives. There are a few different types of belt grinders, and some are better suited for certain applications than others.

One of the most popular options is a 2 x 72 inch belt grinder. This machine has a wider belt that reduces wear and heat buildup, and can be used throughout the entire blade creation process from stock removal to polishing.

Another popular option is a 1 x 30 inch belt grinder, which is a good entry-level grinder for a beginner or hobbyist. These machines have less power than the 2x72s and typically have a 1/3hp motor, but are still a great option for anyone wanting to get into knife making.

If you’re looking for a more affordable option, you can also find a 2×42 grinder, which is more commonly seen on the consumer market and in hardware stores. These machines are similar to the 1x30s in terms of performance, but are more stable and come with a 6″ disc sander.

Tip 2: Build Your Own

If you are a knifemaker, a belt grinder is one of the most essential tools in your arsenal. These versatile machines are commonly used to shape blades, grind bevels, and profile bolsters.

A good belt grinder should be built from materials that are resistant to sparks and high temperatures. You should also look for a motor that has a high horsepower. This is important because the more horsepower a machine has, the more powerful it will be.

A good motor is important because it will withstand the grit and debris that comes off a blade. It is also a good idea to look for a machine that is easy to change belts on, especially if you are an advanced knifemaker. This will help you get the most out of your grinder and make the process easier for you. Lastly, it is best to use a belt sander with an adjustable speed controller, as this will allow you to easily change the belt speed.

Tip 3: Add Accessories

If you’re serious about your knife making business, it’s important to invest in the right tools. Belt grinders are the ideal choice if you’re looking to sand down metal burrs, polish surfaces, and sharpen blades for your customers.

You’ll want to pick a grinder with a high-quality motor. The best ones have plenty of horsepower and feature a nifty variable speed option. This will allow you to customize your blade-sharpening process according to your specific needs and goals.

You’ll also want to make sure you have a bucket of water by your machine. This is because dipping your work in water will mitigate heat buildup that can ruin the finish of your knives and shorten their lifespan. The correct amount of water will help to cool your workpiece while you’re grinding and may be the difference between a successful project and a scrappy flop. Adding the correct accessories to your belt grinder for your knife making needs can make it a more productive tool than ever before.