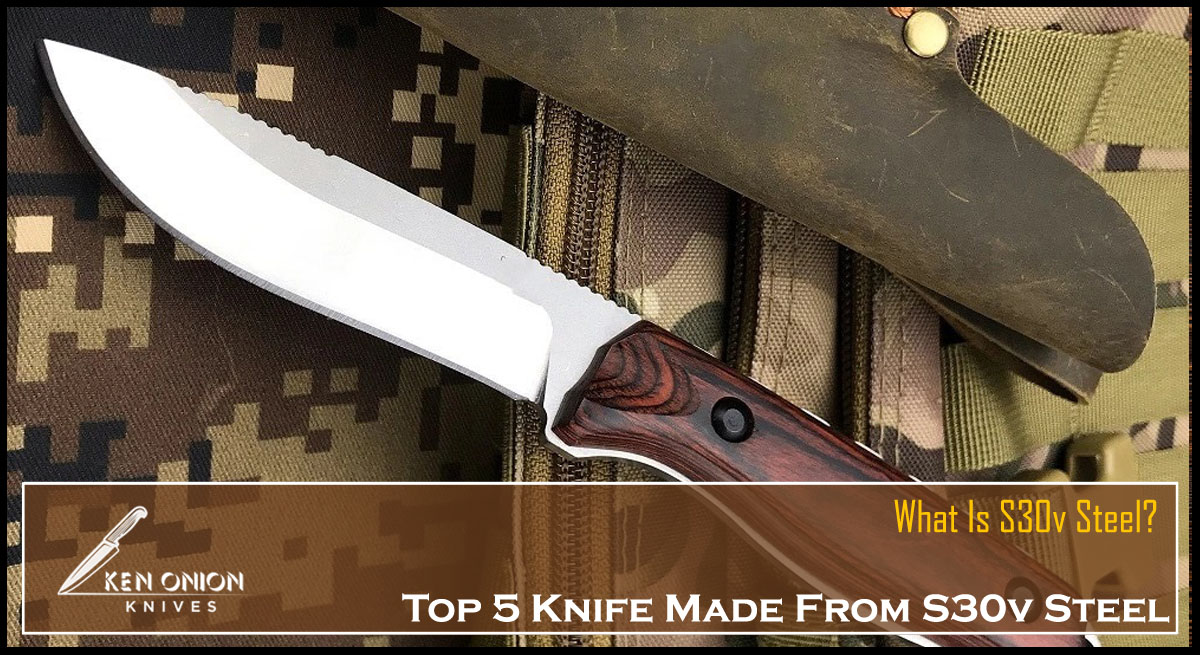

Do you look for What Is S30v Steel? and S30v Steel Is Good For a Knife? As knife enthusiasts, we know different types of steel perform differently. S30v steel is a great performing steel that has stood the test of time. Many knives are made with this steel and it is often a favorite because of its toughness and edge retention.

In this blog post, we’ll discuss what makes s30v steel so great and some of the best knives made with it.

What is S30v steel?

S30v steel is a high-carbon stainless steel that was designed specifically for use in knives. It is often considered the gold standard in the knife industry because it offers an excellent balance of hardness, toughness, and wear resistance.

s30v steel is made with vanadium and chromium, which gives it outstanding properties. One of the most notable characteristics of this steel is its ability to take and hold a very sharp edge. It is also highly resistant to chipping and breaking. In addition, s30v steel has excellent corrosion resistance thanks to its high chromium content.

Top 3 best knives made with s30v steel?

There are a ton of great knives made with s30v steel. In fact, it is one of the most popular steels used in high-end kitchen knives. Some of our favorite s30v knives include:

*Note: Score is based on our AI score (Editor’s choice and rating)

All these knives offer outstanding performance and are made with high-quality materials.

History and properties of S30V steel?

S30V Background.

It’s easy to see how the S30V was developed. It has been around for decades, just like its predecessor 154CM which started getting popular in knives through Bob Loveless’ work back when he created it during the early 1970s!

Crucible is a company famous for its development of powder metallurgy steels that started commercial-scale production in 1970. Powder metal allows higher alloy content and finer microstructure because it forms quickly at room temperature through rapid solidification; you can read more about how this process works here!

The Crucible developed several powder metallurgy sheets of steel including 10V, and S60V (formerly 440), and finally came up with an improved version of their popular 420 steel. Although all three have been used for different purposes over time none were suitable as a knife blade material due to poor grind ability or stain resistance among other things – which means that this type of tool will never be widespread outside custom knives made entirely from it!

The S60V steel has a high carbon content and is not bad for an Ingot, but its poor grind ability makes it less popular than other knife steels. The patent-filed 1995 improvement on this material made it more wear resistant with better toughness/corrosion resistance due to their improvements in these qualities over time such as improving the durability when used today while also maintaining good sharpness because they were designed that way from day one!

Dick Barber, former Crucible metallurgist who was the lead developer on S30V asked Chris Reeve (of CRK) why they were using BG42 steel rather than one of our available products.

The reason for this choice is that it has better corrosion resistance which will allow us to produce knives with a longer lifetime in certain environments such as marine environments where salt water and other chemicals are used regularly.

In search of the perfect steel, Chris Reeve Knives conducted interviews with many knifemakers and knife companies. They talked about what properties they desired in a blade; people like Sal Glesser (the owner of Steakhouse Provisions), Ernest Emerson from Ferrante Forge & Crucible Steel Co., and Tony Marfione who performs research at HRP Company – all helped shape this new industry’s inception!

The goal of the designers was to create steel that had improved properties when compared with BG 42. They succeeded in doing so by using powder metallurgy for S30V’s production, an easily heat-treated material due to its high melting point that also resists corrosion well enough without being too tough or brittle on edge retention levels either way; this makes it perfect as both armor piercing and slicing weapons alike!

Evolution of Steel Design Prior to S30V.

The development of new materials is an important part of the advancement and growth of any industry. The bearing metals, such as 154CM were looking at modifying their existing counterparts by reducing chromium (Cr) content with 3% less than before while adding 4 Mo to see how it would fair against them- only now we find out there are even more similarities between these two elements! It turns out this modification also led toward similar corrosion resistance as 440C does; but what does that mean? In short: thanks largely due to your research team for finding something better one step closer to greener futures everywhere!

The modified steels were developed to maintain similar properties when cooled in different ways. For example, 440C has 5.5% vanadium but S60V only contains 2%. The difference is primarily due to the carbon content which was reduced from 17% down to 14%, making it harder without compromising its ductility or machinability features.

The reason for reducing the Mo and Cr content in steel was not because of their relationship with each other, but rather a competing element: Carbides. These hard particles form when two types of metal compete together over time during the manufacturing process leading to an increased wear resistance while detracting from toughness. The low Cr (5%) steel like 10V contains vanadium which forms the very hard VC carbides that contribute to wear resistance and edge retention.

Chromium also exists in softer chrome WC, but they are dissolved at typical heat-treating temperatures. The chromium-added carbides detract less from the wear resistance, but they also reduce toughness just as much (or more) than vanadium does. This means that a mix of both will produce an even better balance between these two qualities, meaning your blade may last longer without becoming too sharp and potentially causing injury to yourself or others around you when cutting things up!

Carbides are an important part of the world’s supply chain, but they can be difficult to understand. This article breaks down how different carbide types form and what you need for your metalworking shop!

The development team behind S90V reduced the chromium content by 3% and added a corresponding amount of vanadium while maintaining similar carbon levels. This resulted in more carbide, but it’s all made from Vanadyl Carbide which has much higher wear resistance than the regular steel or ceramic materials we use today!

Vanadium carbides make steel more difficult to work with, but the smaller size of these materials means there’s less chromium needed. S90V benefits from this because it has higher-level freedom for corrosion resistance- without all that pesky chrome getting in your way!

To learn about corrosion resistance, be sure to read this article. This table summarizes the properties resulting from different amounts of Chromium Carbide (M7C3), Vanadium Carbides (MC) and measured toughness in a crossed-cylinder wear test with higher being better for both measures: Wear Resistance & Corrosion Against 10% boiling acetic acid solution at room temperature lower numbers mean lessening over time and corrosion rate is given in mm/year.

Design of S30V.

The lesson learned from these lessons is that a lower chromium content allows vanadium to go further in terms of its contribution toward wear resistance. The carbon and vanadium content in steel can make it difficult to grind, but when these elements are reduced the carbide particles within become finer which means they’re more aggressive. This makes for a harder metal that’s easier on tools!

The trade-off for improved toughness and grind ability is a decrease in wear resistance, but this can be made up by using 3% vanadium instead of 10%. To create more balanced steel than S90V with improved toughness and grind ability, we needed to reduce carbon levels as well.

Crucible started out with a metal called 154CM as their basis, but it had too much lead, so they replaced 2% Mo with vanadium. However, to make the steel more wear-resistant, Chris Reeve Knives wanted a material that would better differentiate from BG42. This led to an increase in vanadium by up to 4%. The increase in Mo from 1% to 2%, as seen with the S90V and its 14 percent Cr.

Molybdenum content; provides an even greater level of corrosion resistance than before due largely because this element helps block harmful chemicals like rust from taking hold on your metal surfaces while still allowing some necessary elements through so they can perform their tasks effectively-which includes strengthening bones too!

The addition of 0.2% nitrogen to S30V creates a more durable metal that can withstand heat treatment, making it perfect for tools with high wear rates or environments where they’re going to run into tough materials like pipes at construction sites!

Nitrogen is a flexible element that can be used to create different grades of steel. It does this by changing the alloy content, specifically with chromium and vanadium which both increase its durability but reduce some other properties such as hardness or ductility in certain directions (S30V).

S30V provides improved yield strength, higher impact resistance, and better corrosion resistivity over BG42:

Toughness:

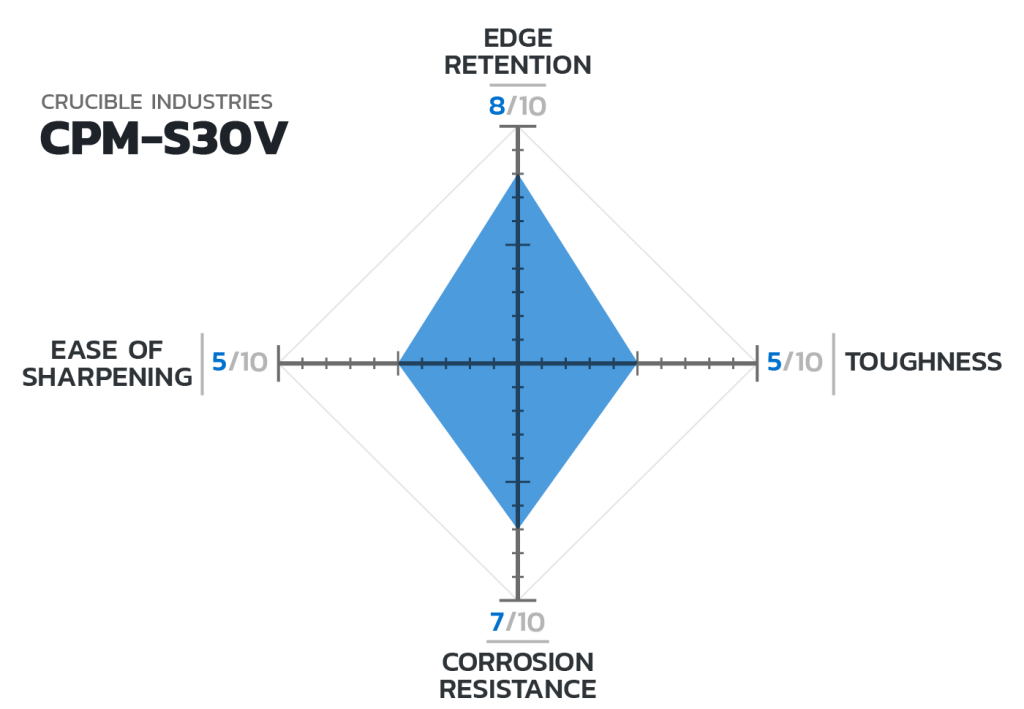

S30V is very tough steel, especially of its hardness level. It’s been designed to be resistant to chipping and breaking under heavy use.

Edge retention:

S30V has outstanding edge retention. It’s able to retain its sharpness for long periods of time, even with heavy use.

Corrosion resistance:

The vanadium addition makes less chromium carbide, which results in better corrosion resistance than BG42 and 154CM.

Properties of S30V.

Heat Treatment Response:

By ensuring the steel could be heated to a temperature no higher than 2000°F, we have made it easy for you to heat treat your own knives. The S30V steel was released at a time when many knifemakers had furnaces limited to temperatures below 2000°F.

It would be difficult, if not impossible for them all to reach full hardness without an alternative method of heating their blade material quickly enough after being heated over higher ranges so as not to prematurely dull or otherwise permanently damage its cutting edge before it has cooled down sufficiently – especially since some methods like radiation may take much longer than others!

The 2% molybdenum addition helped improve hardenability so that slower air quenches could be used. As shown in the datasheet for S30V steel below 64 RC when treated with cold temperatures and easily tempered down to 58-61 Rc range common among many knives today.

Microstructure:

S30V is a very interesting steel with an excellent fine-grained carbide structure. This means that it’s sharper than common 154 CM (BG42) or even some other steels such as S60V and 90/100 variety available before this new material came along!

Edge Retention:

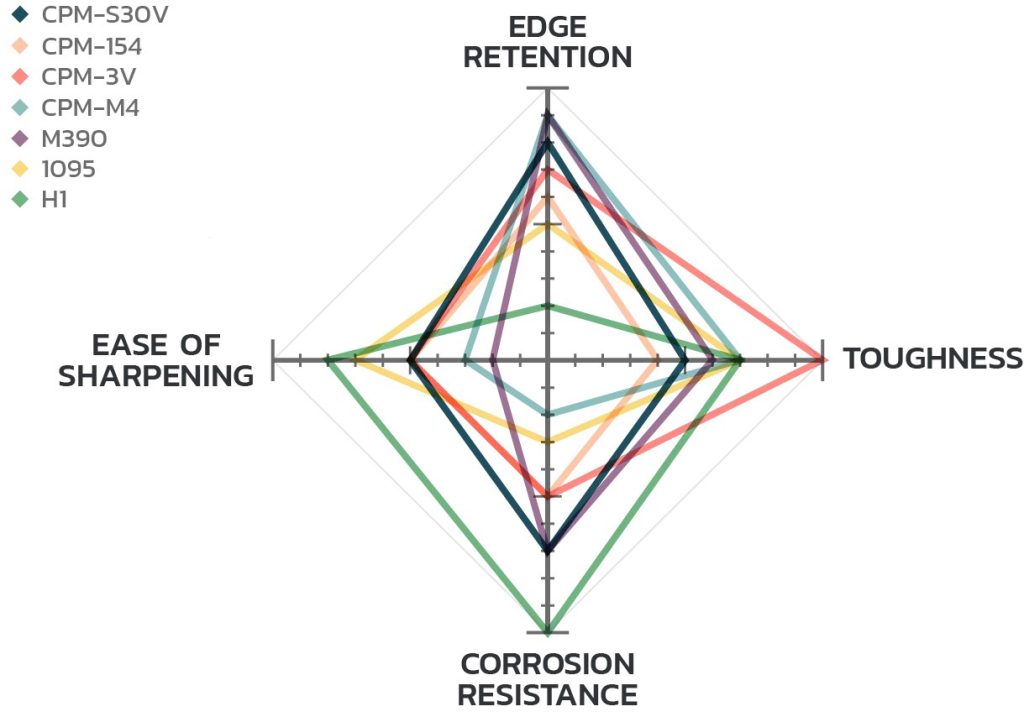

The results from CATRA experiments show that S30V still has good edge retention, better than many other knife sheets of steel like XHP Elmax 154CM 440C, etc. The experiment with S30V showed that it is a bit below steels like ZDP-189, M390, and 20CV. With my own CATRA experiments, we found the relative position of this steel to be approximately the same as these others; however, we will elaborate more on those findings in future articles as testing is not yet completed.

Toughness:

The durability of S30V is like other stainless steel in its class according to my own toughness experiments, though not record-setting as seen on our standard test utilizing unnotched 1/4 size Charpy specimens.

However, we think the toughness of S30V could be further improved with better heat treatment. If we use what we learned from working on heat treatable steels like SPY 27 and 45 VN then perhaps this material’s strength will increase by up to 8 lbs per square inch (psi) at 1-2 RC higher hardness!

Corrosion Resistance:

S30V and S35VN are both much better than CPM-154, with corrosion resistance that we would call “above average”. Knives made of the new S45VN have been shown to be slightly more corrosion-resistant than those with lower numbers. This was also seen in my own testing, where higher ratings below mean better resistance against environmental factors like water or acid for example- so if you’re looking for a top-notch blade then go ahead and choose one from this range!

Legacy of S30V:

S30V has been a popular choice for production and custom knives in recent years. Some even say that the material is boring because of its ubiquity, but we think it’s excellent steel with many uses! The release of S30V in 2001 was one reason why we became a metallurgist and eventually wrote for this website. Modifications to the metal led me on an exciting journey that included creating something even more popular-S35VN, but also recent advancements like 45 VIN Brian Ford Connection: This article will be about how modifications made from pure iron lead us into new territory where we can create different alloys with greater strength than ever before! In the world of stainless steel, S30V is still widely used as an indicator of quality. Other steels will often be compared to it and as a result, the standard has been set high.

Types of s30v steel.

There are two types of s30v steel: the original and the modified.

The original s30v steel was created by adding vanadium and molybdenum to pure iron. This resulted in steel that was harder and more wear-resistant than other steel available at the time.

The modified s30v steel was created by adding chromium, silicon, manganese, and niobium to the original alloy. This resulted in steel that is even harder and more wear-resistant than the original. It is this modified version of s30v steel that is most used today.

What Are S30v Steel’s pros and cons?

Pros.

- It is a very strong and durable steel that can withstand a lot of wear and tear.

- It is also resistant to rusting and corrosion.

- It is easy to sharpen and maintain.

Cons.

- It is a bit more expensive than other types of steel.

- It is not stainless steel, so it may require more maintenance to prevent rusting and corrosion.

Why is s30v steel so popular?

s30v steel is extremely popular among knife makers and enthusiasts for good reason. As we mentioned, it offers an excellent balance of properties that are important for knives. It is also relatively easy to sharpen, which is a big plus.

Many knife makers like to use s30v steel because it allows them to create a very sharp and durable edge.

Caring for your S30v knife.

Keep the blade clean and dry.

It is important to keep the blade of your S30V knife clean and dry when not in use. This will help to prevent rust and corrosion.

Sharpen regularly:

Like all knives, S30V knives need to be sharpened on a regular basis to maintain their performance. Sharpening your knife regularly will also help to prolong its lifespan.

Store properly.

When not in use, it is important to store your S30V knife in a dry and safe place. This will help to keep the blade in good condition and prevent accidents.

Use with care.

S30V knives are designed to be durable and withstand heavy use. However, they are still knives and should be used with care. Be sure to follow all safety precautions when using your knife.

Clean after each use.

It is important to clean your knife after each use to remove any dirt, debris, or moisture that could cause rusting or corrosion.

Apply oil regularly.

To protect the blade from rusting or corrosion, it is important to apply a small amount of oil to the blade on a regular basis.

Inspect the knife regularly.

It is important to inspect your knife regularly for any signs of damage or wear. If you notice any damage, it is important to have the knife repaired or replaced as soon as possible.

FAQs about What Is S30v Steel.

What steel is better than S30V?

The S90v steel is much better at retaining its edge than the less expensive, but softer 30-degree variety. It’s also easier to sharpen and many people find that they can get by with just one sharpening session per year on this type of blade compared with stropping their kitchen knives regularly or using an electric knife if necessary. However, this added hardness comes at a price as the S90v is also more brittle.

Is S30V steel hard to sharpen?

We’ve found s30v to be tough steel when it comes sharpened. Not that this is more difficult, but literally the material itself has an abrasive resistant quality about its surface which makes cutting slightly more challenging for those who use knives with less skilled hands or tools in general. So, for most knife users out there, we would recommend another steel like CPM S35VN.

S30V steel chip?

While not impervious to chipping, S30V is a lot more resistant to it than most other steels. This is because it’s a harder steel, which makes it less likely to deform under stress. However, if you do happen to chip your knife, don’t worry too much as it can usually be fixed with a little bit of work.

What is the difference between S30V and S35VN?

The main difference between S30V and S35VN is that S35VN is newer steel that has been designed to be even tougher and more wear resistant than S30V. Additionally, S35VN is also easier to sharpen than S30V.

How rust resistant is S30V steel?

The S30V steel has an excellent combination of wear resistance and corrosion resistance making it one of the best steels for knives. With 14% Chromium, this material offers great protection from both rusting as well as blade scaling when used properly in your knife design!

Which is better, steel D2 or S30V?

S30V is better steel than D2 for knives because it has a higher level of wear resistance and corrosion resistance. Additionally, S30V is also easier to sharpen than D2.

How much is S30V steel?

S30V steel typically costs between $100 and $200 per knife. However, the price can vary depending on the size and quality of the knife.

What is S30V used for?

S30V is often used in high-end kitchen knives because it offers an excellent balance of properties that are important for knives. It is also relatively easy to sharpen, which is a big plus. Additionally, many knife makers like to use s30v steel because it allows them to create a very sharp and durable edge.

How long does S30V steel last?

S30V steel is designed to be extremely durable. With proper care, your S30V knife can last for many years. However, like all knives, it will eventually need to be sharpened or replaced.

What can I use to sharpen my S30V?

There are several different types and grades of steel, but we would recommend using carbon steel or VG 10 kinds in your sharpening practice. It is difficult to remove burrs on high vanadium carbide blades with these materials.

How can I sharpen my S30V knife?

There are several different ways to sharpen your S30V knife. You can use a sharpening stone, honing rod, or electric sharpener. Be sure to follow the manufacturer’s instructions carefully to avoid damaging the blade.

How to sharpen my S30V steel?

First, you need to rinse the knife with warm water to remove any dirt or debris that may be on the blade.

Next, you will need to use mild soap and a soft cloth to clean the blade. Be sure to avoid using harsh chemicals or abrasive cleaners as they can damage the blade.

Once the blade is clean, you will need to dry it off completely to prevent rusting.

Finally, you will need to apply a small amount of oil to the blade to protect it from corrosion.

Once you have finished, you can store your knife in a safe place until it is needed again.

How often should I sharpen my S30V knife?

It is generally recommended that you sharpen your knife every few months. However, if you are using it frequently or for heavy duty tasks, you may need to sharpen it more often.

Is S30V steel magnetic?

Yes. Knife steels are often changeable depending on how they’re used. For example, when steel is heated up in the oven or cooked with fire for long periods of time it changes crystal structure from one form to another and will go back into magnetic mode once cooled down again. However, there are several different types of knife steels that are not magnetic.

How can I tell if my knife is S30V?

There are a few ways to tell if your knife is S30V. One way is to look for the stamp on the blade that says “S30V.” Another way is to take a magnet and see if it sticks to the blade. If it does, then your knife is most likely made of S30V steel.

How to use s30v steel?

Choose the right knife: When looking for a new knife, it is important to keep in mind what you will be using it for. S30V is a great option for those who need a durable and reliable blade that can withstand heavy use.

Keep it clean: It is important to keep your S30V knife clean and dry when not in use. This will help to prevent rust and corrosion.

Sharpen regularly: Like all knives, S30V knives need to be sharpened on a regular basis to maintain their performance. Sharpening your knife regularly will also help to prolong its lifespan.

Store properly: When not in use, it is important to store your S30V knife in a dry and safe place. This will help to keep the blade in good condition and prevent accidents.

Use with care: S30V knives are designed to be durable and withstand heavy use. However, they are still knives and should be used with care. Be sure to follow all safety precautions when using your knife.

How to clean s30v steel?

First, you need to rinse the knife with warm water to remove any dirt or debris that may be on the blade.

Next, you will need to use mild soap and a soft cloth to clean the blade. Be sure to avoid using harsh chemicals or abrasive cleaners as they can damage the blade.

Once the blade is clean, you will need to dry it off completely to prevent rusting.

Finally, you will need to apply a small amount of oil to the blade to protect it from corrosion.

Once you have finished, you can store your knife in a safe place until it is needed again.

How often should I clean my S30V knife?

It is generally recommended that you clean your knife after each use. However, if you are using it for heavy duty tasks or in a dirty environment, you may need to clean it more often.

What is the best way to store my S30V knife?

When not in use, it is important to store your S30V knife in a dry and safe place. This will help to keep the blade in good condition and prevent accidents. A kitchen drawer or cabinet is a good option.

My S30V knife is starting to rust, what can I do?

If your knife is starting to rust, you will need to clean it and dry it off completely as soon as possible. Once it is dry, you can apply a small amount of oil to the blade to help protect it from further corrosion.

What should I do if my S30V knife is damaged?

If your knife is damaged, it is important to have it repaired or replaced as soon as possible. Using a damaged knife can be dangerous and may cause further damage to the blade.

S30V knives are designed to be durable and withstand heavy use. However, they are still knives and should be used with care. Be sure to follow all safety precautions when using your knife.

What Is S30v Steel? Final Thought

S30v steel is a great choice for knives. It has good edge retention and can withstand a lot of wear and tear. If you’re looking for a knife that will hold its sharpness over time and can take a beating, then s30v steel is the right option for you.

Have you tried out one of our s30v steel knives yet? We think you’ll love them!

Related Post: